Since my sewing table has all manner of sewing notions on it, that leaves minimal design workspace. My other work surfaces are two round table and they just aren't appropriate for working on a fairly large project. For years I have used a 4" x 8" x 1/2" felt covered piece of plywood as a portable design and photography "wall". It dawned on me today that I could move the two round tables a bit closer together and span the plywood "wall" between them. Perfect! It's not pretty, but it sure works.

A site dedicated to fiber arts, art quilts, soft sculpture, surface design, and optimizing techniques in other artistic media.

Pages

▼

Tuesday, January 25, 2011

Unorthodox Extension for Sewing Table

In order to make room in my diminutive living room for a fairly large Christmas Tree last month, I moved a rather small library table to the studio and plopped it up against my sewing table, just to keep it out of the way. Serendipity can lead to most wonderful ideas. As I was working on a fairly large quilt, it draped out onto the library table and this made the machine quilting process much easier that it is to wrangle the whole thing on one's lap.

After the holidays, the tree came down and I toyed with the idea of leaving the library table against the sewing table, but that really wasn't possible because I use that table as a laptop computer and printer table. It dawned on me that I had purchased two tripod type roller arm systems to handle large pieces of wood that roll off my table saw in the garage. I still don't know why I purchased two. I suppose the price was too good to pass up.

I put the adjustable height roller unit together, found a scrap piece of 1/4"" plywood, covered it with clear vinyl, clamped the plywood to the table with the other end of the plywood resting on the roller assembly. This makes a nifty extension for the sewing table and it's other great features are that it is light weight, can easily be disassembled and can easily be put away if more floor space is needed. Here 'tiz.

After the holidays, the tree came down and I toyed with the idea of leaving the library table against the sewing table, but that really wasn't possible because I use that table as a laptop computer and printer table. It dawned on me that I had purchased two tripod type roller arm systems to handle large pieces of wood that roll off my table saw in the garage. I still don't know why I purchased two. I suppose the price was too good to pass up.

I put the adjustable height roller unit together, found a scrap piece of 1/4"" plywood, covered it with clear vinyl, clamped the plywood to the table with the other end of the plywood resting on the roller assembly. This makes a nifty extension for the sewing table and it's other great features are that it is light weight, can easily be disassembled and can easily be put away if more floor space is needed. Here 'tiz.

Drats and Double Drats - Serger Threading Problem

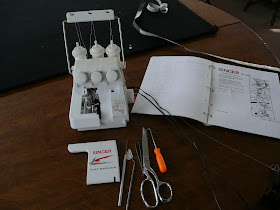

Before prewashing fabric so that I can paint the background for a new quilting project, I pulled out my eency weency Singer TS +TS380 serger so that the edges wouldn't fray in the washing machine. The serger is almost like a toy but it works just fine for small projects that don't require the finished precision of the higher level sergers. When I first bought it, it took me 3 hours and ordering an instruction book online to get the darned thing threaded but pure stubborness got the deed done. I swore at that time that I would never, ever thread the thing again. I found that one can change threads by tying the ends of threads togehter and running them through the threading mechanism so that rethreading would not be an issue.

Much to my chagrin this morning I found that the thread on one of the spools had broken. Oh, no, Mr. Bill! I hauled out the instruction booklet but there was absolutely no way for me to get the darned thread through the backside hole of the 3rd little serger arm. Guess I'll have to take it to a sewing machine place and pay someone to do it for me. Rats.

Here's the little devil...

Much to my chagrin this morning I found that the thread on one of the spools had broken. Oh, no, Mr. Bill! I hauled out the instruction booklet but there was absolutely no way for me to get the darned thread through the backside hole of the 3rd little serger arm. Guess I'll have to take it to a sewing machine place and pay someone to do it for me. Rats.

Here's the little devil...

Exciting News from Mia Bloom Designs

I found out from Mia that she has multiples of her cards so I bought the heart with the flames. Now, I need to also buy one each of these.

You, too, can have one of these unique cards by Mia Bloom Designs. Just visit her shop at:

http://www.etsy.com/shop/MiaBloomDesigns

You, too, can have one of these unique cards by Mia Bloom Designs. Just visit her shop at:

http://www.etsy.com/shop/MiaBloomDesigns

A Great Find - MIA BLOOM DESIGNS!

Mia Bloom, a superbly creative art quilter, has a new store on Etsy that presently features three of her fiber arts Valentine cards and I WANT THIS ONE.

For a visual treat I highly recommend that you check out Mia's blog at

http://miabloomdesigns.blogspot.com/

and her Etsy Store at

http://www.etsy.com/shop/MiaBloomDesigns

For a visual treat I highly recommend that you check out Mia's blog at

http://miabloomdesigns.blogspot.com/

and her Etsy Store at

http://www.etsy.com/shop/MiaBloomDesigns

Friday, January 21, 2011

Pocket Book for Fiber Arts Post Cards

I belong to Serendipity Play Group, a mini group of Quilts on the Wall in Southern California. The focus of the group is on creating and exchanging 5" x 7" quilted, fiber arts post cards. A recent project is for each member to create his or her own "pocket book" for the post cards that are exchanged. Because my grandmother called her purse a pocket book, that image has always been among my fondest memories; thus, my take on the pocket book was the shape of a purse.

My Completed Pocket Book

Yarn Fringe Looped Through Binder Rings

Side View that Shows the Edges of Various Pages

How and Where to Insert the Post Card

Three Sets of Buttonholes were Made to Accommodate the Binder rings

(inside view)

Three Sets of Buttonholes were Made to Accommodate the Binder Rings

(Outside view)

Page Example with Clear Vinyl Stitched around Three Sides

and Yarn Stitched around Four Sides

Example of Page Back

with Handsewn Vinyl Pocket to Hold Card Documentation

Washers Sewn to Each Page

Another View of Washer Attachment

A Handle Was Sewn to the Back Side Edge of the Pocket Book and

Heart Shaped Buttons were Stitched to the Front Edge.

The Clousure Consists of Loops of Cording That Were Stitched to the Back Edge

and Looped Over the Heart Buttons

View of Various Pages

Open Pocket Book

Final View of Completed Pocket book